Repairs

We provide professional repairs for all common compressed air systems and components.

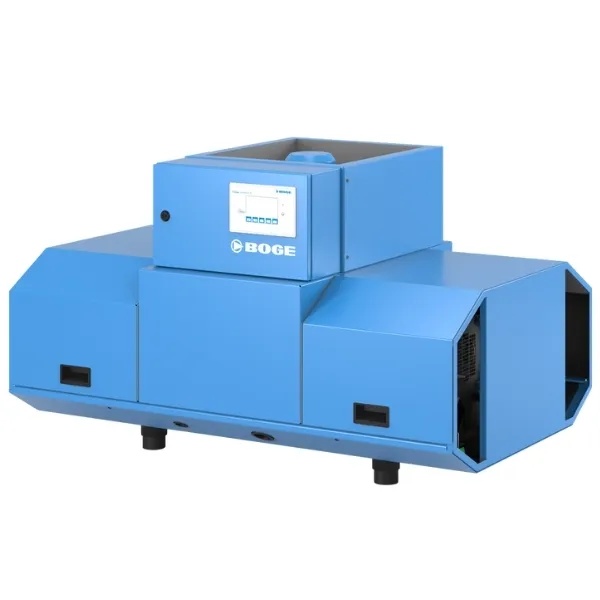

Screw Compressors

We carry out professional repairs on screw compressors of all manufacturers. Our service technicians inspect all relevant components, replace worn parts, and ensure optimal performance and energy efficiency.

We use only original spare parts and guarantee precise alignment and a safe test run directly on-site.

Piston Compressors

We perform complete overhauls of piston compressors, from small workshop units to large industrial systems. This includes valve cleaning, piston replacement, and detailed lubrication analysis.

Our goal is to ensure a long-lasting and powerful compressed air supply with minimal downtime and maximum operational safety.

Construction Compressors

On construction sites, reliability is essential. We repair and maintain mobile construction compressors from all manufacturers, on-site or in our modern workshop in Leipzig.

With fast diagnostics, thorough cleaning, and complete functional testing, we ensure your units are ready for operation again in the shortest possible time.

Dental Compressors

In the dental sector, hygiene, quiet operation and reliability are essential. We perform specialized repairs and maintenance on dental compressors, including filters and drying units.

With great care, we ensure that the compressed air quality meets the strict requirements of medical environments.

Refrigeration Dryers

Efficient and energy-optimized refrigeration dryers are crucial for consistent compressed air quality. We perform leak checks, refrigerant inspections, and replacement of heat exchangers and condensate drains.

This keeps your compressed air system reliably dry, efficient and low-maintenance.

Adsorption Dryers

We handle complete refurbishment and regeneration of adsorption dryers. This includes replacing desiccant material, checking valves, and optimizing control systems.

With our experience, we ensure consistently high air quality and energy-efficient operation of your systems.

Vacuum Pumps

Whether oil-lubricated or dry-running, we repair vacuum pumps from all major brands. This includes seal inspections, replacement of worn rotors, and detailed oil analysis.

A final full-load performance test ensures the consistent capacity and reliability of your system.

Pneumatic Tools

We restore your pneumatic tools to full performance—from impact wrenches to grinding tools. Our workshop checks torque, airflow, and sealing systems and cleans all components thoroughly.

By replacing worn parts, we ensure your tools operate efficiently, precisely and reliably again. Our workshop tests performance and functional safety and guarantees long service life by using original spare parts.