Plant Engineering

We deliver efficient container solutions for safe and long-lasting compressed air and gas supply systems.

Industrial Plant Engineering

In the field of plant engineering, AirDry Systems implements fully integrated compressed air and gas systems precisely tailored to the requirements of our industrial clients. Our turnkey solutions are based on high-quality BOGE compressors, advanced filtration technology, and intelligent control systems – developed for maximum operational safety and efficiency.

From concept and design to commissioning, we provide modular system solutions that adapt flexibly to various production environments. Whether as a compact skid unit, expandable production system, or fully integrated compressed air station – each system is individually engineered and optimized for maximum reliability, energy efficiency, and ease of maintenance.

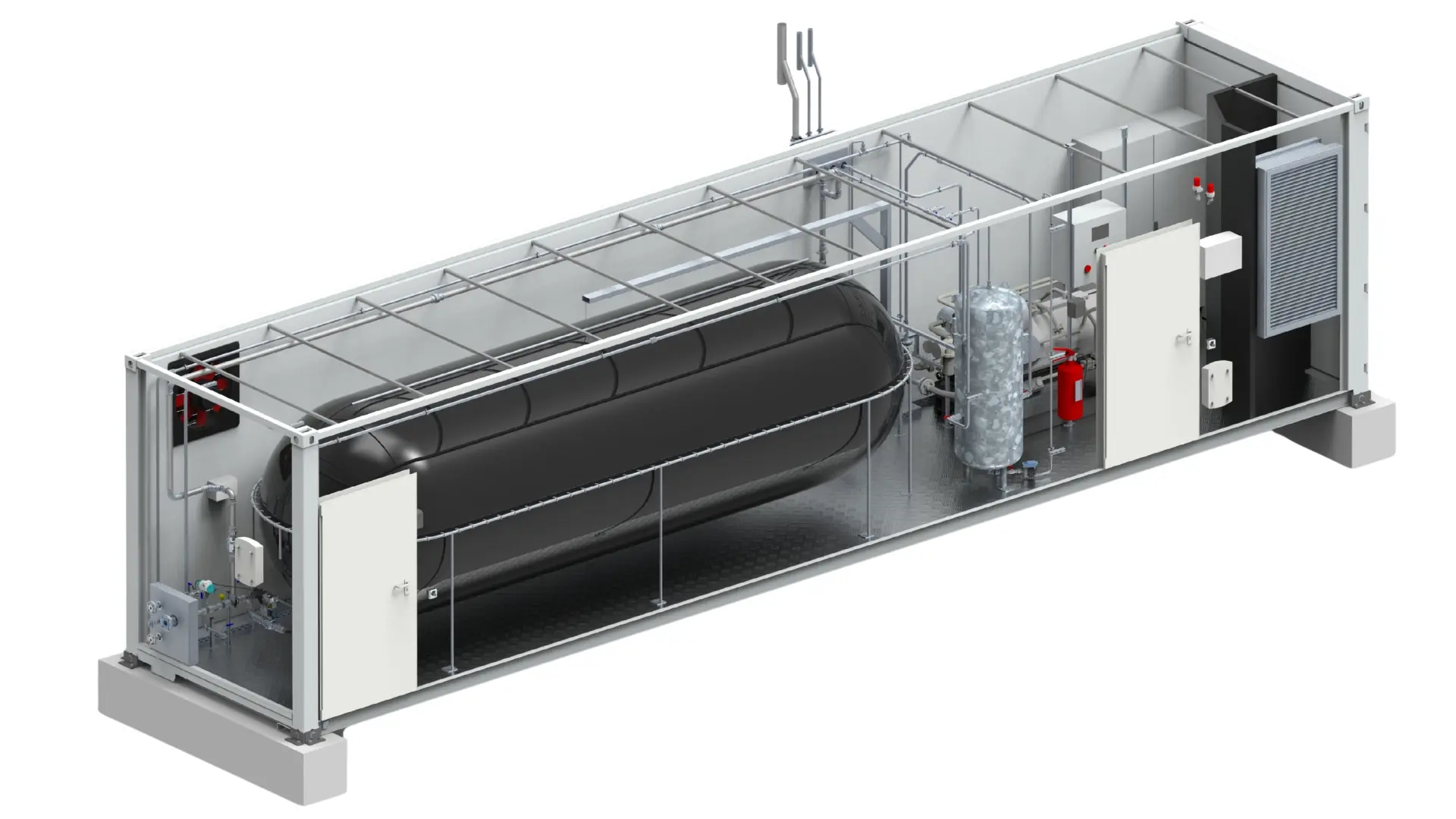

CO₂ Container System

Our CO₂ container systems are compact, fully preconfigured units designed for the reliable treatment and supply of carbon dioxide. They are ideal for industrial applications where purity, pressure stability, and safety are top priorities.

Each system is individually engineered – including control technology, sensors, heat exchangers, and redundant safety systems. Thanks to the container design, installation and transport are highly efficient, and commissioning can take place directly at the operation site.

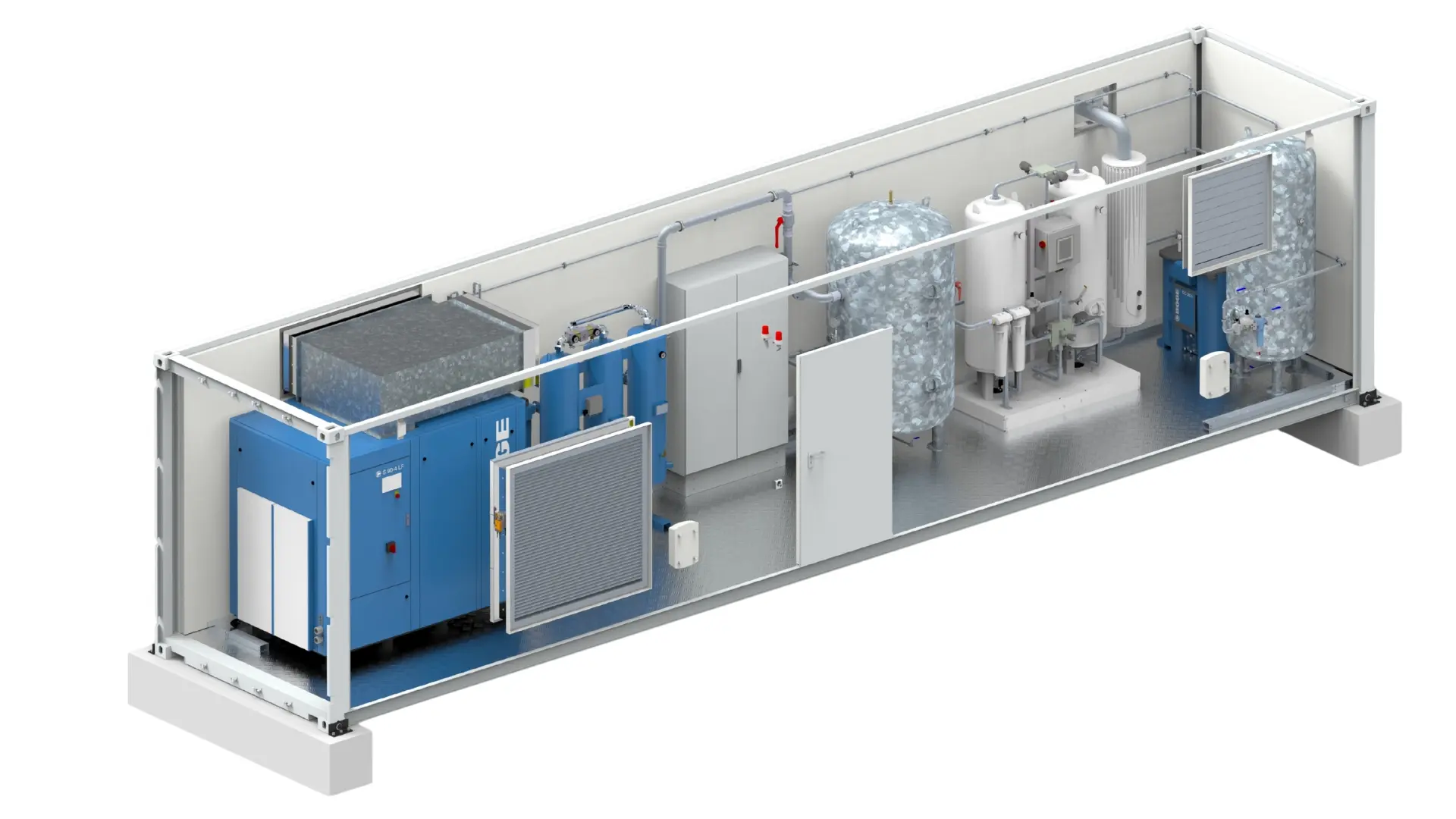

N₂ Compressor Container System

Our N₂ compressor systems enable flexible, mobile nitrogen supply using container-based designs. These units include state-of-the-art BOGE compressors, filtration systems, and control technology to ensure energy-efficient, low-maintenance, and reliable gas production.

Thanks to their modular structure, extensions and custom adaptations are easily implemented – suitable for small production facilities as well as large-scale industrial applications.

Project Story

We developed a complete container system for aircraft production and accompanied the entire process up to commissioning.

Engineering & Planning

Based on the requirements of the production facility, AS Airdrysystems GmbH developed a compact and energy-efficient compressed air container solution. The focus was on optimal air routing, vibration decoupling and service accessibility.

All components were carefully selected and planned in a modular structure to ensure a durable and safe system configuration.

Construction of the Container System

The complete interior installation took place at our facility: BOGE compressors, adsorption dryers, tanks, safety technology and a precisely aligned supply and exhaust air system.

The pre-assembled system was fully tested and prepared for on-site connection – including electrical systems, sensors and control technology.

Transport to the Customer

The fully pre-assembled system was loaded onto a heavy-duty truck. Thanks to the compact container design, the transport was especially efficient and easy to schedule.

All connections were prepared in such a way that only minimal installation time was required on site.

Crane Placement & Commissioning

On site, the container was precisely positioned using a crane and then connected mechanically and electrically.

After successful commissioning, the system now reliably supplies a central production line in aircraft manufacturing with compressed air.