Your Partner for Innovative

Compressed Air Technology

Reliable solutions for industry, trade and dental technology.

Contact UsAbout Us

We develop technical systems for industrial applications with a focus on precision and efficiency.

A Look Into Our Work

AS Airdrysystems GmbH develops reliable, efficient, and technically advanced solutions for compressed air, measurement, and supply systems. With extensive experience, we support projects from planning to final commissioning, standing for precision, safety, and long-term economic efficiency.

We rely on certified technologies, close cooperation with partners, and the highest quality standards to ensure optimal results in industry, dental technology, and energy efficiency.

Our Core Services

The key areas of our work where we apply decades of focused expertise.

Dental

Oil-free and hygienic systems for medical applications.

Plant Engineering

Planning, installation and commissioning of complete compressed air systems.

Measurement Technology

Analysis, leakage testing and efficiency optimization.

E-Mobility

Technical solutions for charging infrastructure and testing.

Repairs

Fast diagnostics, original parts and professional repairs.

Compressors

Sales, service and optimization of modern compressor systems.

Our Suppliers

A selection of our reliable partners providing high-quality components.

Our Certificates

Our certificates stand for top quality, expertise and many years of technical experience.

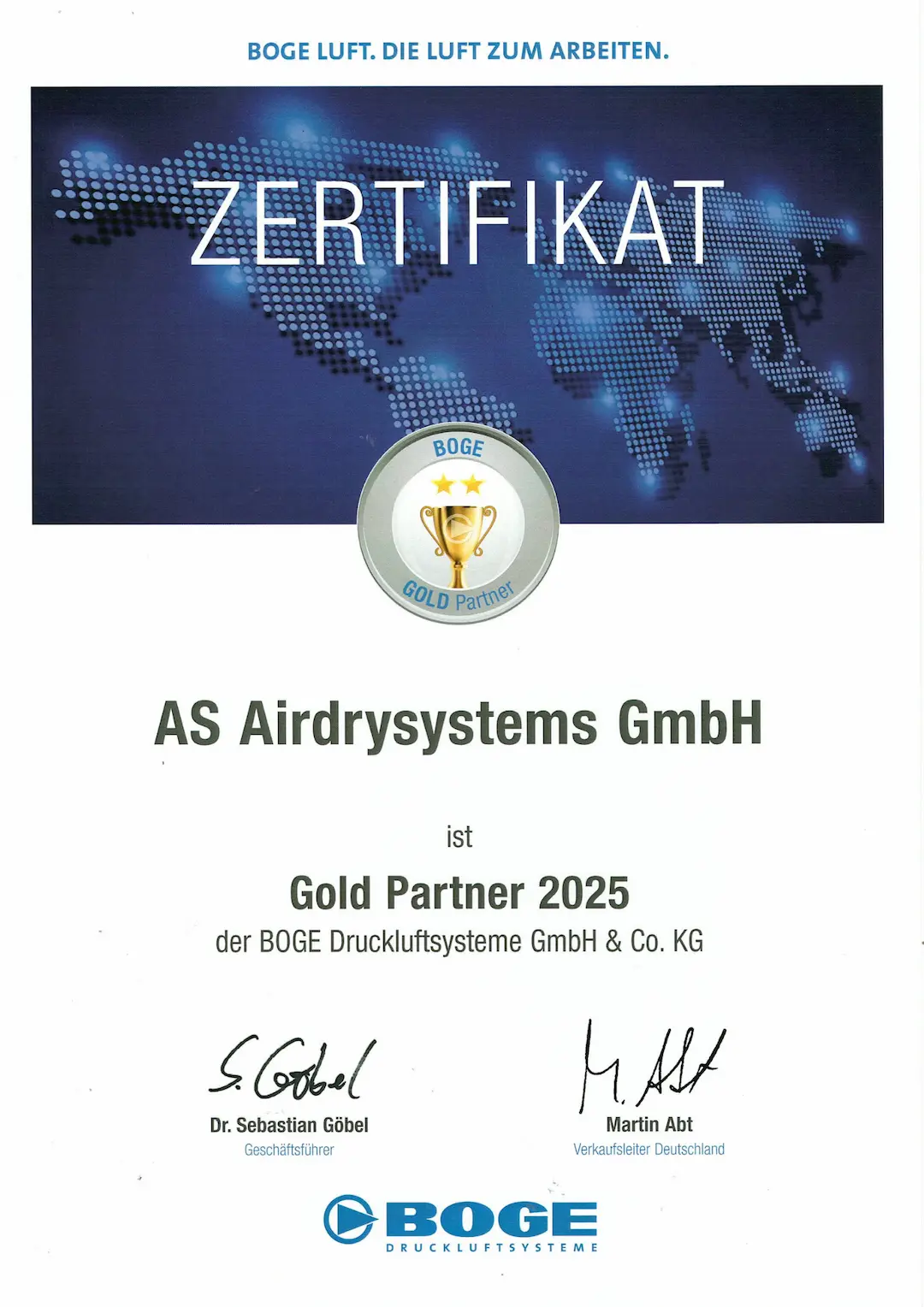

BOGE Gold Partner 2025

As a certified BOGE Gold Partner, AS Airdrysystems GmbH is one of the most qualified specialist companies in Germany for compressed air and compressor technology. This certification is awarded only to companies that demonstrate consistent quality, extensive technical expertise and proven successful project execution.

Our close partnership with BOGE gives us direct access to state-of-the-art technologies, rapid technical support and exclusive training. As a result, our customers benefit from exceptionally reliable, energy-efficient and long-lasting compressed air solutions.

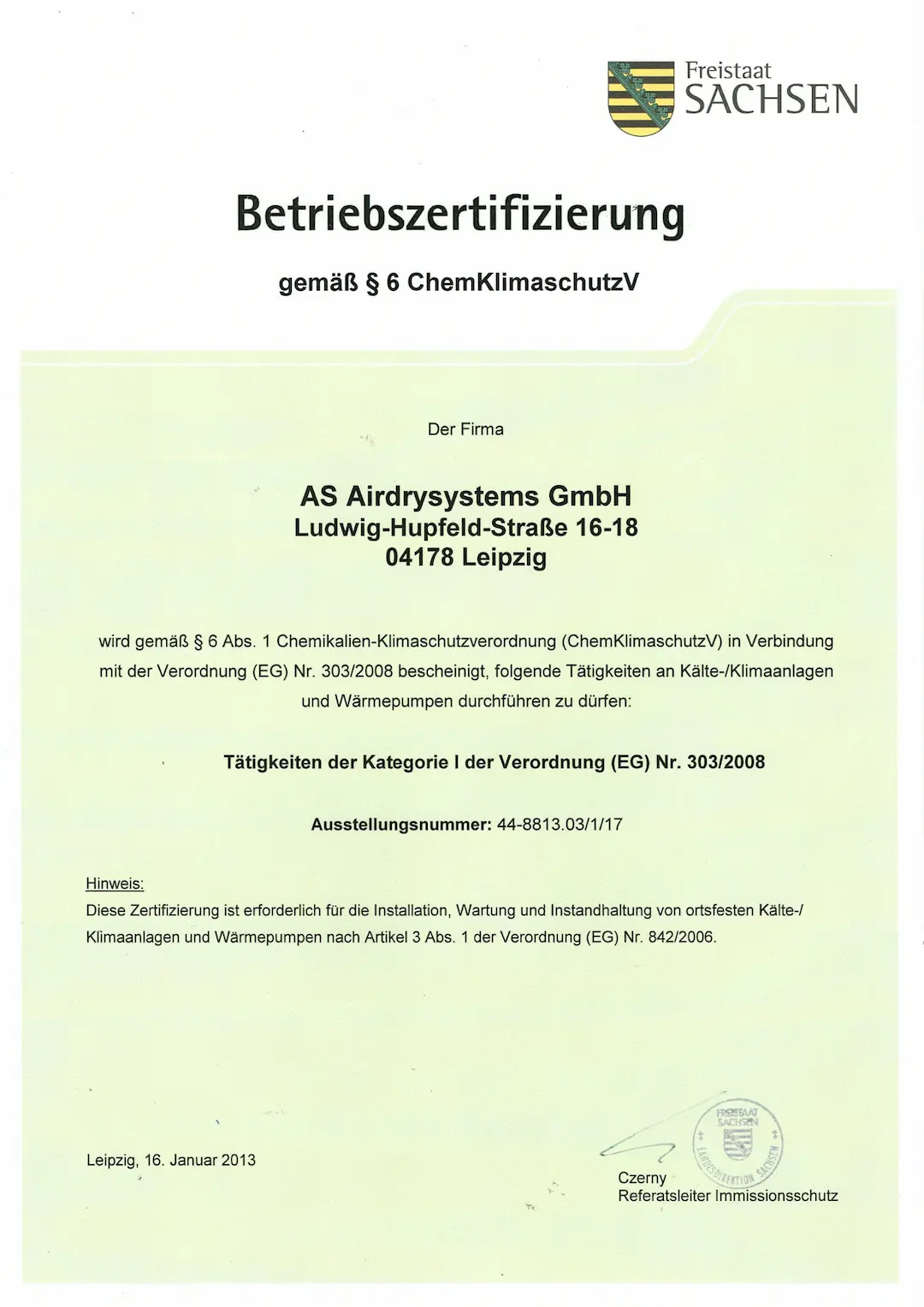

Certification according to § 6 ChemKlimaschutzV

AS Airdrysystems GmbH is certified in accordance with § 6 of the Chemical Climate Protection Ordinance and is officially authorized to carry out work on refrigeration, air conditioning and heat pump systems of Category I. This highest qualification level permits work on all system types and refrigerant quantities.

For our customers, this ensures maximum safety, professional installation, repair and maintenance, as well as compliance with all applicable EU standards and environmental regulations. Our certified technicians ensure that systems operate efficiently, durably and in full legal compliance.

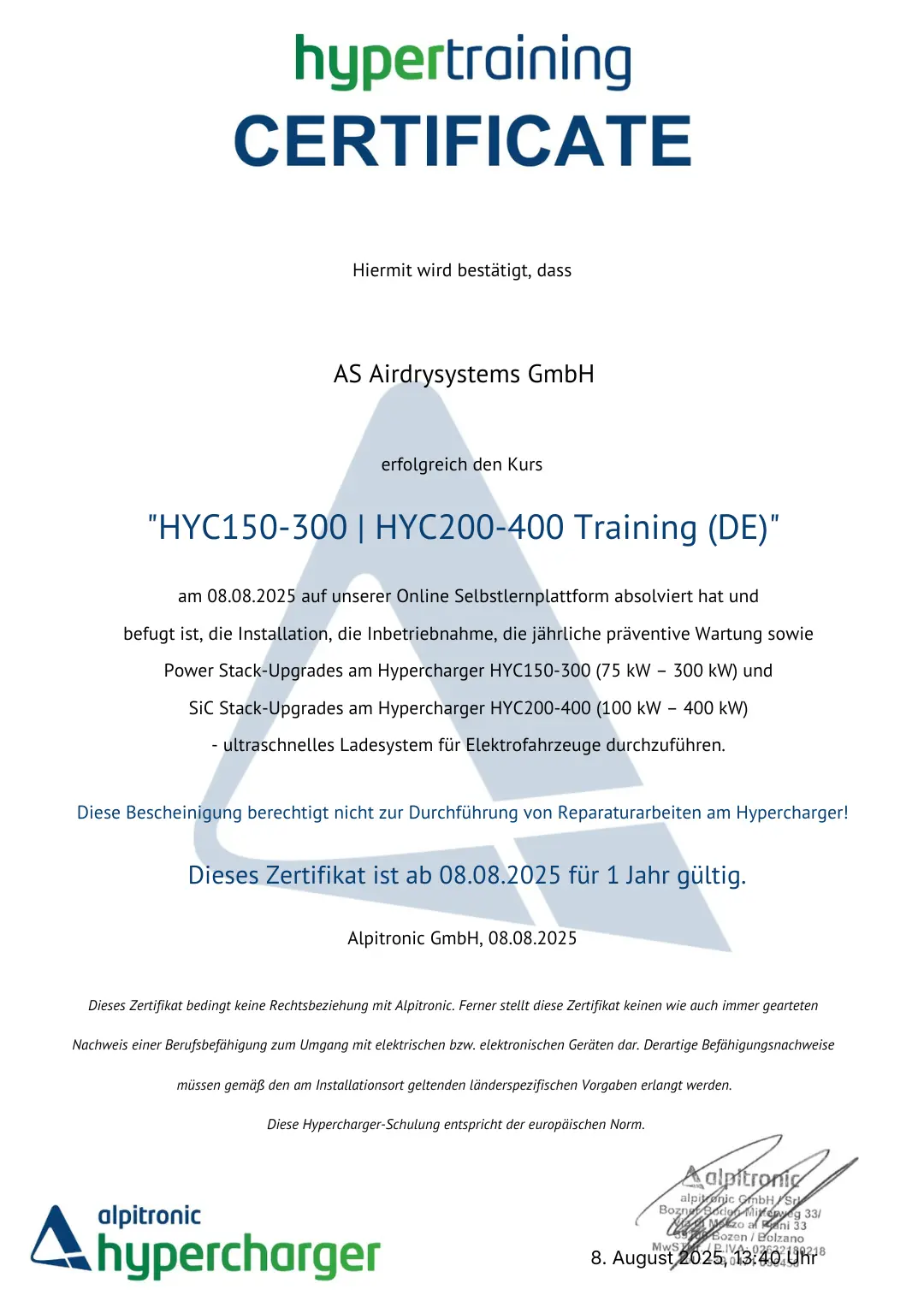

Hypercharger Training HYC150–300 / HYC200–400

AS Airdrysystems GmbH has successfully completed the Hypercharger training for the HYC150–300 and HYC200–400 models. This certification authorizes us to professionally install, commission, and perform annual preventive maintenance on ultra-fast charging systems for electric vehicles.

Through this certification, we possess in-depth technical expertise in high-power charging infrastructure and are authorized to carry out power stack and SiC stack upgrades on the specified Hypercharger systems in accordance with the manufacturer’s guidelines.

Project Story

We developed a complete container system for aircraft production and accompanied the entire process up to commissioning.

Engineering & Planning

Based on the requirements of the production facility, AS Airdrysystems GmbH developed a compact and energy-efficient compressed air container solution. The focus was on optimal air routing, vibration decoupling and service accessibility.

All components were carefully selected and planned in a modular structure to ensure a durable and safe system configuration.

Construction of the Container System

The complete interior installation took place at our facility: BOGE compressors, adsorption dryers, tanks, safety technology and a precisely aligned supply and exhaust air system.

The pre-assembled system was fully tested and prepared for on-site connection – including electrical systems, sensors and control technology.

Transport to the Customer

The fully pre-assembled system was loaded onto a heavy-duty truck. Thanks to the compact container design, the transport was especially efficient and easy to schedule.

All connections were prepared in such a way that only minimal installation time was required on site.

Crane Placement & Commissioning

On site, the container was precisely positioned using a crane and then connected mechanically and electrically.

After successful commissioning, the system now reliably supplies a central production line in aircraft manufacturing with compressed air.

Our Google Reviews

Authentic feedback from people who have worked with us.

Ich bin ein Lieferant

Ohne Kommentar

Ohne Kommentar

Ohne Kommentar

Tiptop

Hier wird man als Handwerker vom Dach fair und respektvoll behandelt. 👌💪👍

Ohne Kommentar

Contact Us

Fill out the form and we will get back to you as soon as possible.

Our Location

Here you can see our exact company location at a glance.

Please accept cookies to load the Google Maps map.